-

Product DescriptionCompany Info.<>

- Principle:

- Vacuum filtration

- Style:

- Vertical type

- Applicable object:

- Lubricating oil

- Model:

- ZJB-30Z

- Filter type:

- Fibre

- Performance:

- High efficiency filtration

- Rated flow:

- 0.6 m3/h

- Working pressure:

- 0.4 MPa

- Operating noise:

- 60-80 dB

- Inlet and outlet pipe diameter:

- 25 mm

- Deemulsification number:

- 15 min

- Cleanliness:

- 6-8 NAS

- Overall dimension:

- 1250*1000*1500 mm

- Effective filtration area:

- 0.33 ㎡

- Machine power:

- 15 kw

- power supply:

- 380V50HZ

ZJB-30Z transformer oil mobile oil filter dehydration degassing improve withstand voltage multifunctional oil filter

Single-stage vacuum water removal impurity removal vacuum oil-water separation vacuum degassing

size: 1250*1000*1500mm

Filter Usage:

Application:ZJB series oil filter can quickly remove water, gas and impurities from insulating oil, reduce dielectric loss, improve oil insulation performance and oil quality. It can effectively ensure the normal operation of power equipment and avoid accidents.

Equipment features: This machine can meet the requirements of vacuum pumping of transformer body on installation or maintenance site, and complete degassing and dehydration treatment of transformer oil at the same time, shortening the oil treatment period. It integrates precision filtration, high efficiency dehydration, degassing, vacuum stereo evaporation technology and automatic control technology of oil, simple operation, safe and reliable operation.

1, high filtration accuracy, large amount of dirt, can remove fine suspended particles in the oil.

2, unique degassing, dehydration materials, its evaporation area is hundreds of times larger than conventional materials.

3, this machine has the characteristics of small and efficient, easy to move, especially suitable for on-site live work.

4. The system adopts advanced fuzzy oil temperature device, which can set the upper and lower limits of oil temperature arbitrarily, so that the oil temperature can be controlled in intervals.

5, high degree of automation, oil level automatic control and automatic protection, safe and reliable, simple and convenient operation.

Oil Filter Product Features:

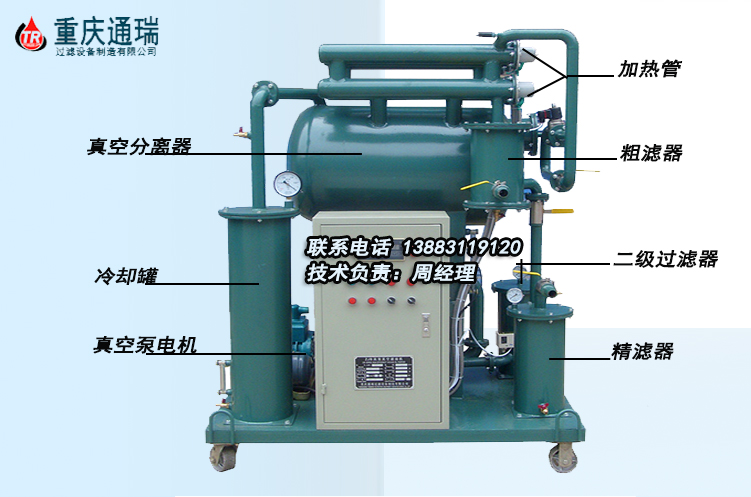

Working principle: ZJB-30Z transformer oil mobile filter unit work, oil under the action of internal and external pressure difference through the inlet into the primary filter, large particles of impurities are filtered out, oil after multi-stage infrared heating, into the special personalized vacuum separator, in the vacuum separator first formed mist, and then formed film, so that its contact area in vacuum expanded to hundreds of times the original, water in the oil in high heat, high vacuum, large surface, high pumping speed conditions to be rapidly vaporized and discharged by the vacuum system.

The water vapor discharged from the upper part of the vacuum separator is cooled and dehumidified by the condenser, cooled again in the cooler, condensed water is discharged into the water reservoir, and the gas after twice condensation and dehumidification is discharged into the air by the vacuum pump.

The dried oil after vacuum vaporization and dehydration in vacuum separator is raised from negative pressure to positive pressure by oil transfer pump, and after filtration, the purified oil is discharged from the oil outlet to complete the whole oil purification process.

◆Filter system:

This machine uses multi-level progressive encryption filter settings.

◆ Heating system:

The heating system consists of heater, temperature controller, over-temperature protector and other parts; under the action of pressure, the oil to be treated flows through the heater for heat exchange heating, the heat load on the surface of the heating pipe is 1.5w/c㎡, and the water in the oil is boiled by heating, which is beneficial for the next evaporation. The temperature controller can monitor the temperature of the heating system in real time and control the heater to work within a set temperature range; when the heater temperature exceeds the protection set point, the over-temperature protector works to cut off the operation of the heater, ensuring the safety of equipment and personnel.

◆ Vacuum system:

Vacuum system consists of vacuum separator, vacuum pump, condenser cooler and other parts. In the vacuum separator, there is an evaporation unit matched with the model, which improves the evaporation area from the geometric level to ensure that the oil has a sufficient evaporation surface, which is conducive to the rapid extraction of gas by the vacuum source according to the gas flow characteristics. Vacuum pump pumping speed capacity is evaporated water vapor, precipitation of gas more than twice the amount to ensure that the oil is not secondary pollution, while ensuring that the system is in a very low pressure state.

◆ Automatic control and protection system:

Automatic control system consists of sensors, motors, solenoid valves, control elements, protection elements and other parts.

1) When the oil temperature reaches the set point, the temperature controller sends a signal to stop the heater, otherwise it can be heated;

2), when the heater temperature exceeds the set value (factory setting is 65℃) over-temperature protection signal heater stops working;

3) The oil intake is controlled by bypass valve and regulating solenoid valve. When the oil intake is too large and rises to the limit oil level, the regulating solenoid valve is closed to stop the oil intake of the machine. Otherwise, the oil intake solenoid valve is opened;

4) The pressure controller factory pressure protection control point is set to 0.4Mpa, reaching the set point, the whole machine stops working and alarms;

◆ Cooling and condensing system:

It is composed of condenser, cooler, water reservoir and other parts.

The vapor and other gases evaporated in the vacuum separator are cooled and dehumidified by the condenser, cooled again in the cooler with blocking exchange medium, and the reduced condensed water is discharged into the water reservoir. The dry gas after twice condensation and dehumidification is discharged into the air by the vacuum pump, thus protecting the vacuum pump.

Filter technical parameter table:

Transformer oil mobile oil filter equipment related parameters

nominal flow rate

1.8m3/h

working vacuum

-0.065~ -0.096Mpa

with a controlled range

20~80℃

oil pump pressure

<0.5Mpa

Noise db (A)

65~85 db(A)

power supply

480V/60HZ

heating power

15 KW

machine power

17 KW

inlet and outlet diameter

DN 20

Appearance size mm

1250*1000*1500

installation (unit) weight

400kg

after-sales service commitment1. The warranty period of vacuum oil filter machine is one year (except consumables). During the warranty period, major problems of equipment shall be subject to three guarantees. Any abnormal problems shall be handled by the supplier free of charge. If they occur outside the warranty period, the supplier shall provide lifelong free technical service and only charge the cost of accessories.2. The supplier guarantees that the equipment provided meets the user's requirements for safe production and reliable operation, and is fully responsible for the design, manufacture, test, supply, shipment, on-site commissioning and other processes of the equipment;3. Within the specified quality warranty period, the supplier shall be responsible for any defects and failures caused by defects in the design process or materials, and shall be fully responsible for the losses caused.4. After the equipment is put into operation, if the supplier needs to provide door-to-door service due to product quality reasons, the supplier shall respond within 2 hours after receiving the written notice from the buyer, and arrive at the site within 72 hours after the time agreed by both parties.

Chongqing Tongrui ZJB-10 dehydration degassing to improve the voltage value of transformer oil filter,100%quality assurance, product sales at home and abroad!

Chongqing Tongrui ZJB-10 dehydration degassing to improve the voltage value of transformer oil filter,100%quality assurance, product sales at home and abroad!

Specifications are different, prices are different, please contact the manufacturer before ordering, we will make *** accurate recommendations for you! , Manager Zou .- Name(chinese)

- Name(English)

- Chongqing Tongrui Filtration Equipment Manufacturing Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Chongqing, China

- Nearby port

- Dalian,Tianjin,Qingdao,Yantai,Nanjing,Lianyungang,Shanghai,Ningbo,Zhoushan,Xiamen,Shenzhen,Guangzhou,Zhuhai,Zhanjiang,Haikou

Chongqing Tongrui Filtration Equipment Manufacturing Co., Ltd.(Contact person: Zou Ling. Tel: 13883119120) is a company that develops and manufactures oil filtration and purification equipment. Dedicated to the development of oil filtration and purification equipment, our company mainly manages: YL three-level filtration refueling machine, ZJB transformer oil vacuum filter, ZJD lubricating oil vacuum filter ZJC turbine oil dehydration oil filter ZJD-K hydraulic oil plate and frame filter vacuum oil filter ZJD-F light oil coalescence, separation and filtration equipment BK plate and frame filter oil, etc. Chongqing Tongrui Filtration Equipment Manufacturing Co., Ltd. welcomes friends from all walks of life to visit, provide guidance and business negotiation.- Name(chinese)

- Name(English)

- Chongqing Tongrui Filtration Equipment Manufacturing Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Chongqing, China

- Nearby port

- Dalian,Tianjin,Qingdao,Yantai,Nanjing,Lianyungang,Shanghai,Ningbo,Zhoushan,Xiamen,Shenzhen,Guangzhou,Zhuhai,Zhanjiang,Haikou

Chongqing Tongrui Filtration Equipment Manufacturing Co., Ltd.(Contact person: Zou Ling. Tel: 13883119120) is a company that develops and manufactures oil filtration and purification equipment. Dedicated to the development of oil filtration and purification equipment, our company mainly manages: YL three-level filtration refueling machine, ZJB transformer oil vacuum filter, ZJD lubricating oil vacuum filter ZJC turbine oil dehydration oil filter ZJD-K hydraulic oil plate and frame filter vacuum oil filter ZJD-F light oil coalescence, separation and filtration equipment BK plate and frame filter oil, etc. Chongqing Tongrui Filtration Equipment Manufacturing Co., Ltd. welcomes friends from all walks of life to visit, provide guidance and business negotiation. -

Send your message to this supplier*From:*To:

Mrs. Lyn

*Message:

Mrs. Lyn

*Message:

Copyright © 2003 - 2026 Goepe.com All rights reserved.